Fire resistant fabrics are essential for many industries and applications where protection from fire and heat is crucial. Choosing the right fire resistant fabric depends on factors like the level of protection needed, comfort, durability, and cost. This complete guide provides an overview of different types of fire resistant fabrics, their key properties and uses, and tips for selecting the best option for your needs.

Table of Contents

What are Fire Resistant Fabrics?

Fire resistant fabrics are designed to resist ignition, inhibit flame spread, and resist melting and dripping when exposed to flame or intense heat. They are made from fibers and finished with chemicals that help them perform better compared to regular textiles when met with fire or heat.

The main purposes of fire resistant fabrics are:

- Provide protection by resisting ignition and heat transfer

- Self-extinguish when the ignition source is removed

- Resist melting and dripping to prevent burns

- Maintain their integrity and shape when exposed to fire

Fire resistant fabrics should not be confused with fireproof fabrics. Fireproof means the fabric will not ignite, burn, melt, drip or support combustion in air. No fabric is fully fireproof, but fire resistant fabrics provide varying degrees of protection and resistance depending on the type of fabric.

Types of Fire Resistant Fabrics

There are several main types of fibers used to make fire resistant fabrics, including:

1. Nomex

Nomex is a synthetic fire resistant fiber created by DuPont. It is an aromatic polyamide polymer that chars rather than melts when exposed to flame. Nomex has excellent thermal stability and low flammability. It is blended with other fibers like Kevlar and cotton to make fire resistant fabrics.

Key features:

- Withstands temperatures up to 370°C

- Highly resistant to ignition and melting

- Durable even after repeated laundering

- Comfortable, breathable and lightweight

Uses: Firefighting gear, auto racing suits, electrical insulation, military uniforms, hazmat suits.

2. Kevlar

Kevlar is another synthetic fiber made by DuPont using aromatic polyamide polymers. It has high tensile strength and heat resistance. Kevlar is often mixed with other fibers like wool, cotton and Nomex.

Key features:

- Maintains strength and flexibility when exposed to flames

- Withstands temperatures up to 500°C

- Cut and abrasion resistant

- Lightweight

Uses: Firefighter turnout gear, welding aprons, gloves, military uniforms.

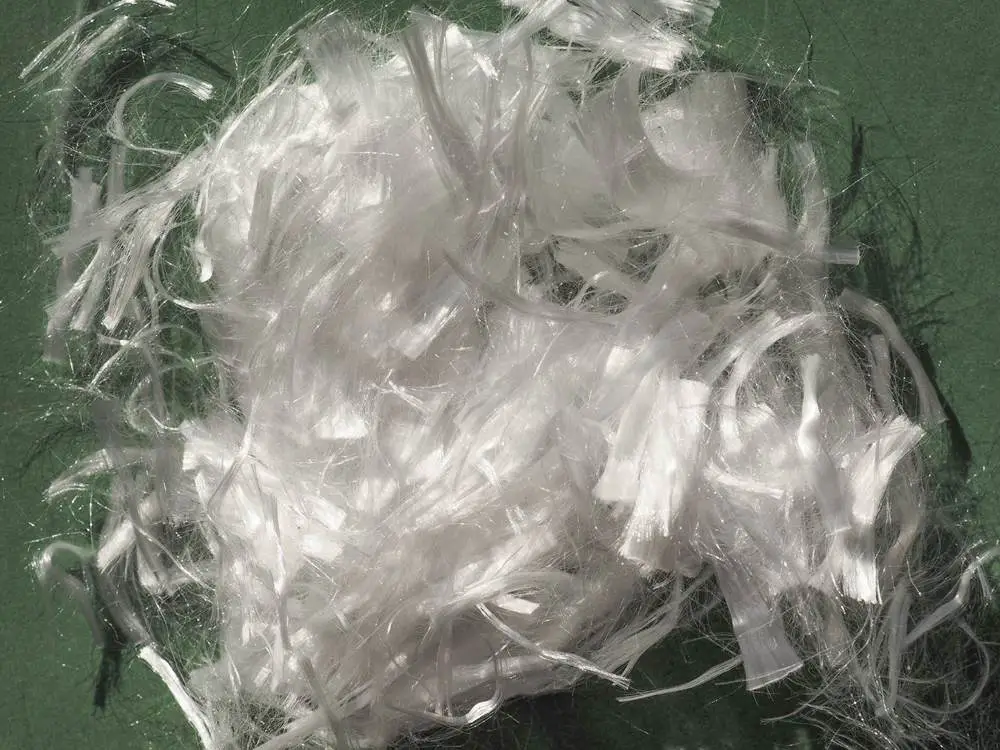

3. Carbon Fiber

Carbon fibers are made by carbonizing (pyrolyzing) synthetic fibers like rayon, polyacrylonitrile (PAN) or petroleum pitch. They have very high heat resistance and do not melt, soften or form toxic fumes when subjected to flame.

Key features:

- Withstand extremely high temperatures above 1000°C

- Very low flammability and conductivity

- Strong and lightweight

- Expensive

Uses: Racing suits, aircraft and aerospace composites, high temperature insulation.

4. Modacrylic

Modacrylic is a modified acrylic fiber that is inherently flame resistant. It can be mixed with wool or cotton for fire resistant fabrics.

Key Features:

- Self-extinguishing properties

- Maintains shape and fabric integrity when burned

- Soft, warm, lightweight

- Resilient, easy to dye

Uses: Children’s sleepwear, blankets, carpets, uniforms, upholstery.

5. Meta Aramid & Para Aramid

These are synthetic polyamides with flame resistant properties. Meta aramid is used to make Nomex while para aramid is used to make Kevlar. They have high heat resistance and durability.

Key Features:

- Withstand temperatures between 500-1000°C

- Lightweight, soft and flexible

- Not affected by most chemicals

Uses: Firefighting gear, electrical insulation, welding gloves, military uniforms.

6. Wool

Wool has natural fire resistant properties due to its high moisture and nitrogen content. It is often blended with synthetics for improved performance.

Key Features:

- Naturally flame resistant

- High ignition temperature

- Insulating and moisture wicking

Uses: Firefighter base layers, gloves, socks, suits, uniforms.

7. Fire Resistant Cotton

Cotton can be treated with chemicals like ammonium phosphate, organophosphates, and borax compounds to make it fire resistant. It is blended with synthetics to enhance protection.

Key Features:

- Inexpensive

- Soft, breathable and comfortable

- Treated cotton provides better protection than plain cotton

Uses: Workwear, uniforms, bedding, curtains.

8. Polybenzimidazole (PBI)

PBI is a synthetic fire resistant fiber with high heat and flame resistance. It does not easily ignite, melt or support combustion.

Key Features:

- Withstands temperatures up to 500°C

- Very low flammability and smoke emission

- Strong, lightweight and flexible

Uses: Firefighter gear, industrial protective apparel, aircraft interiors.

Properties of Fire Resistant Fabrics

Some key properties to evaluate in fire resistant fabrics:

- Ignition Resistance – How easily the fabric ignites and sustains burning when exposed to a flame or heat source.

- Heat Transfer Resistance – How well the fabric blocks heat transfer to the skin to prevent burns. Measured in seconds or cal/cm2.

- Thermal Shrinkage – The extent of fabric shrinkage when exposed to high heat. Minimal shrinkage indicates better thermal stability.

- After Flame – How long the fabric continues burning after removal of ignition source. Shorter times are preferred.

- Afterglow – Duration of residual smoldering after flame is removed. Shorter afterglow indicates faster self-extinguishing.

- Char Length – Length of burned area after fabric is exposed to flame. Shorter char length indicates better protection.

- LOI (Limiting Oxygen Index) – Minimum concentration of oxygen needed to sustain burning. Higher LOI = more flame resistance.

- TPP (Thermal Protective Performance) – Time it takes for heat from a flame to transfer through a fabric to cause a 2nd degree burn. Higher TPP = better protection.

- Arc Rating – The level of protection a fabric provides against an electrical arc flash. Measured in cal/cm2. Higher arc rating indicates better protection.

Applications and Uses of Fire Resistant Fabrics

Fire resistant fabrics have become indispensable across many industries and applications where protection from fire and heat is needed including:

- Firefighting gear – Turnout coats, trousers, gloves, hoods, boots and accessories. Must provide heat, flame and abrasion resistance. Most commonly made from Nomex, Kevlar and PBI blends.

- Petrochemical industry – Protective clothing for oil rig workers, refinery operators, chemical plant employees to shield from flash fires and explosions. Nomex and treated cotton are common.

- Military and law enforcement – Flame resistant uniforms, bomb suits, gloves, helmets, shields. Kevlar, Nomex and wool blends are commonly used.

- Auto racing – Suits, gloves, shoes, helmets and balaclavas worn by race car drivers must be fire resistant and retardant. Primarily made from Nomex, carbon fiber, wool, or treated cotton blends.

- Maritime industry – Workwear for offshore, marine, and fishing operations requires FR protection. Nomex and flame resistant cotton are common.

- Electrical utilities – Protective clothing needed for utility workers to shield against arc flashes and burns. Choose arc-rated fabrics like Nomex.

- Welding – Leather or FR cotton welding jackets, aprons and gloves prevent sparks, spatters and heat from igniting clothes underneath.

- Space program – Fire resistant fabrics are essential for spacecraft and space suits to protect from extreme heat during atmospheric re-entry. PBI is commonly used.

Choosing the Best Fire Resistant Fabric

Key factors to consider when selecting the optimal fire resistant fabric include:

Desired Level of Protection

Determine the degree of flame and heat resistance needed for the application. Firefighting gear requires maximum protection while utility worker uniforms permit lightweight, breathable FR fabrics. Compare fabric properties like TPP, LOI and arc rating to match the level of protection needed.

Comfort and Breathability

The fabric should not be too heavy, stiff or uncomfortable for routine wear. Breathable, moisture wicking fabrics help reduce heat stress. Wool, modacrylic and specially engineered blends optimize comfort.

Durability and Care

The fabric must remain protective after repeat laundering and wear. Check expected life span and garment care guidelines. Nomex, Kevlar, PBI and modacrylic have good durability. Avoid FR treated cottons which lose protection over time.

Cost

Synthetic fibers like Nomex tend to be more expensive than FR treated cottons. But they provide far superior protection and durability. Compare cost to expected product lifespan when choosing economical options.

Industry Standards

Check that the fabric meets established industry standards like NFPA 2112, EN533 index 1-3, EN11612, EN11611, etc. Reputable manufacturers will provide certification proof.

Manufacturer Reputation

Select reputable textile manufacturers like DuPont, Milliken, TenCate, Westex, etc. with extensive experience producing FR textiles tested to meet rigorous safety standards.

Care and Maintenance of Fire Resistant Clothing

Proper care and maintenance is essential to retain the flame resistant properties of FR clothing:

- Follow the fabric manufacturer’s specific washing and drying instructions. High heat can degrade FR properties.

- Wash FR clothing separately from regular items. Use mild detergent and avoid bleach, softeners or harsh chemicals that may negate FR properties.

- Tumble dry on low heat or hang dry. Avoid over drying.

- Iron only if needed at lowest setting. Do not use steam or starch.

- Check for wear, damage or holes and repair or discard if found.

- Keep FR clothing clean of grease, oil and other flammable contaminants.

- Store in a clean, dry place away from sunlight. Avoid contamination.

- Hand wash and hang dry FR clothing with special moisture barriers or linings.

- Some FR fabrics like Nomex retain protection after home washing. Others like FR treated cotton lose protection over time.

- Consider professional FR clothing restoration if washings decrease FR performance. They can re-apply flame retardant treatments.

- Replace FR garments once they no longer provide adequate protection.

Fire Resistant Fabric Certifications

There are numerous standards and certifications used to rate and validate the effectiveness of fire resistant fabrics:

- NFPA 2112 – National Fire Protection Association standard for flame resistant garments for protection against flash fires.

- NFPA 70E – National Fire Protection Association standard for protective clothing against workplace electrical hazards. Specifies minimum arc rating required.

- EN533 (Index 1-3) – European standard that rates garment resistance to convective and radiant heat. Index 3 indicates the highest protection.

- EN11612 – European standard for protective clothing against heat and flame. Specifies testing methods and performance levels.

- EN11611 – European standard for garments that protect during welding and allied processes.

- ISO 11612 – International standard equivalent to EN11612.

- ASTM F1506 – American standard that specifies standard test methods and performance requirements for flame resistant textiles and clothing.

- ASTM F1930 – American standard test method for determining arc thermal performance value (ATPV) of fabrics.

- CAN/CGSB 155.20 – Canadian standard for workwear providing protection against flames and electric flashes.

Look for certifications from reputable testing agencies like Underwriters Laboratories (UL), Occupational Safety & Health Administration (OSHA), Safety Equipment Institute (SEI), and FM Approvals on high quality fire resistant fabrics and clothing.

Frequently Asked Questions

Q: Are fire resistant fabrics flame proof?

A: No fabric is 100% flame proof or fireproof. Fire resistant fabrics are designed to resist ignition, inhibit flame spread and slow heat transfer. But they will burn if exposed to sufficient heat flux over time. They aim to provide protection for escape or rescue.

Q: How is cotton made fire resistant?

A: Cotton can be treated with flame retardant chemicals such as tetrakis hydroxymethyl phosphonium chloride, diammonium phosphate, decabromodiphenyl oxide and borax compounds. These interfere with the combustion reaction to make cotton more difficult to ignite and slower to burn. However, the protection diminishes after multiple launderings.

Q: What is the most comfortable fire resistant fabric?

A: Lightweight, breathable fabrics that wick moisture tend to provide the most comfort for extended wear. Fabrics like Nomex, wool, modacrylic and specially engineered FR cotton blends optimize comfort while providing protection.

Q: What is the strongest fire resistant material?

A: Carbon fiber is one of the strongest and most heat resistant fabrics, capable of withstanding extremely high temperatures above 1000°C. It has very low flammability and conductivity. Kevlar and Nomex fibers also have very high tensile strength and heat resistance.

Q: Why is Nomex yellow/green in color?

A: Nomex fibers contain a small amount of yellow or green pigment added during the production process. This provides the signature yellowish-green color. The pigment helps enhance the UV resistance of the Nomex fiber.

Conclusion

There are a wide variety of fire resistant fabrics to suit diverse protection needs. Key factors to consider are the required level of protection, comfort, durability, care requirements and cost. Popular FR fabrics include Nomex, Kevlar, modacrylic, wool, treated cotton and carbon fiber blends. Proper selection, use and maintenance of fire resistant fabrics and clothing is crucial to remain protected from flames, arc flashes and intense heat.