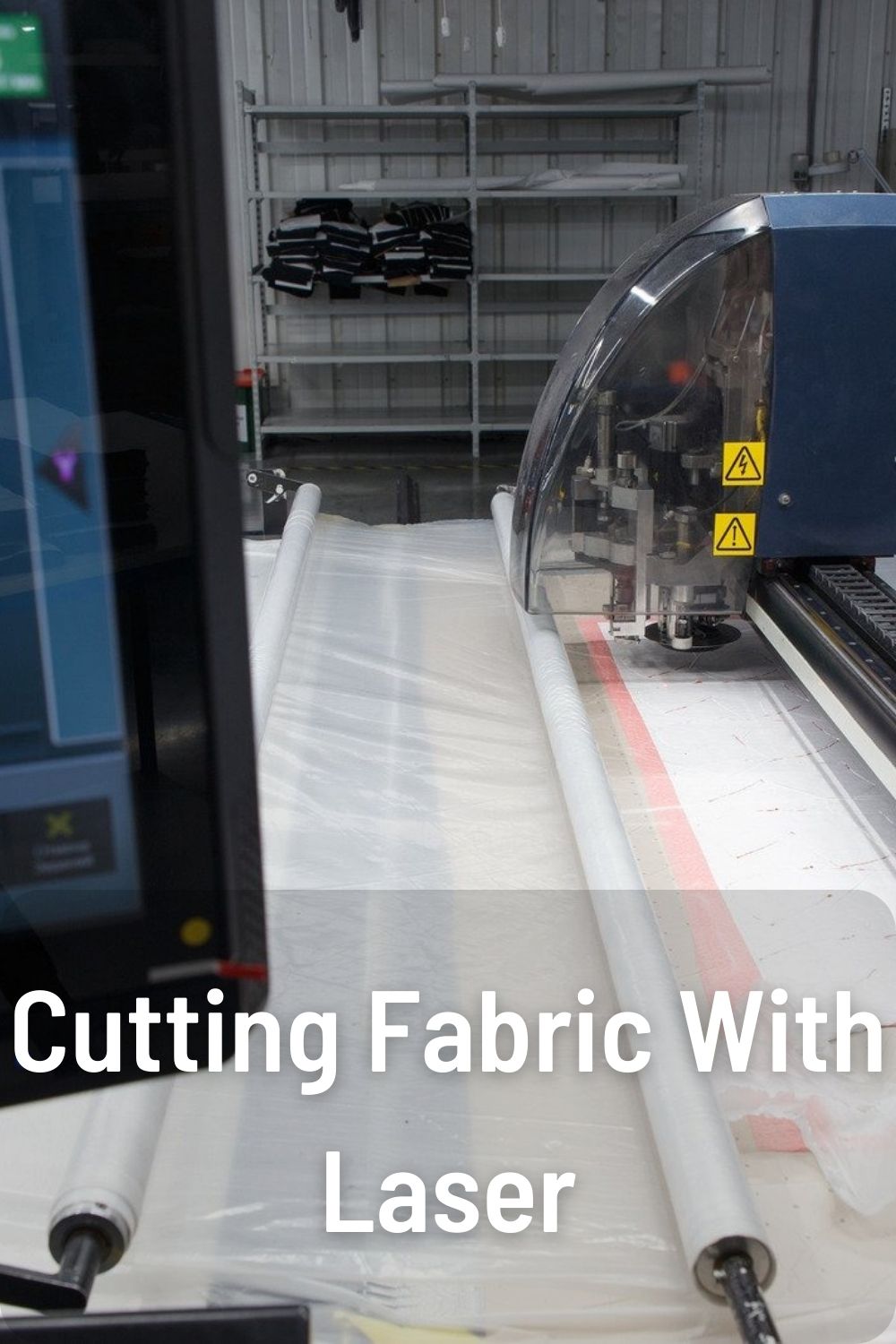

Laser cutting fabric has revolutionized the textile and fashion industries. With laser cutting machines, fabric can be cut with unprecedented precision, speed and efficiency compared to traditional manual and mechanical cutting methods.

In this comprehensive guide, we will cover everything you need to know about cutting fabric with lasers, including:

Table of Contents

How Laser Cutting Fabric Works

Laser cutting uses a high-power laser beam to melt, vaporize or burn fabric along the designated cut lines. The laser beam is directed by computer-controlled mirrors or lenses to trace patterns onto the fabric.

There are two main types of lasers used:

CO2 Lasers

CO2 lasers use a combination of carbon dioxide, helium and nitrogen gases as the lasing medium. CO2 lasers produce a beam in the far infrared region of the electromagnetic spectrum at a wavelength of 10.6 microns.

CO2 lasers can cut through fabric quickly and are suitable for cutting most natural and synthetic fabrics.

Fiber Lasers

Fiber lasers use a semiconductor diode to pump a ytterbium-doped optical fiber medium, which produces near-infrared light at 1.06 microns wavelength.

Fiber lasers are more precise than CO2 lasers and are better for delicate or intricate cuts on synthetic fabrics.

| Laser Type | CO2 Laser | Fiber Laser |

|---|---|---|

| Wavelength | 10.6 microns | 1.06 microns |

| Precision | Moderate | High |

| Speed | Very Fast | Fast |

| Best for | Most fabrics | Synthetics, delicate cuts |

As the laser beam comes in contact with the fabric, the intense heat of the focused spot causes the material to burn, melt or vaporize along the path of the laser. This severes the bonds of the fabric fibers and creates a clean, accurate cut line.

An exhaust system removes the heat, gases and debris during the cutting process. High-pressure assist gas may also be used to blow away melted material as the laser moves along the cut line.

Benefits of Laser Cutting Fabric

Compared to manual cutting tools like scissors or traditional die cutting machines, laser cutting offers many advantages:

Precision and Accuracy

Laser cutting results in smooth, clean cut lines with tighter tolerances compared to mechanical cutting. Lasers can cut complex curves, points and angles with sharp corners and straight edges.

This allows for more intricate patterning and cut-out details not possible with other methods. The precision leads to less fabric waste.

Speed

Lasers cut fabric very quickly, up to hundreds of meters per minute for simpler shapes. This high productivity results in faster order turnaround times.

Flexibility

Laser cutting is highly programmable and flexible. The laser can be controlled to cut virtually any shape imaginable. Design changes can be easily implemented by modifying the digital file.

This allows for customization and on-demand production runs, without the setup costs of dies associated with die cutting.

Versatility

Modern lasers can cut all types of fabrics, from silks and satins to denim, canvas and technical textiles. Lasers can also cut fabrics layered on top of each other.

This allows lasers to handle the diverse materials and requirements across the fashion and textile industries.

Automation

Laser cutting fabric is highly automated, with computerized control of the laser and multi-zone working areas. This results in 24/7 productivity with minimal supervision.

Automation reduces labor costs and human errors associated with manual cutting. Loaders and unloaders can automatically handle rolls of fabric.

Safety

There are no mechanical cutting blades that can become dull or pose injury hazards. The laser beam is contained within the machine enclosure during operation.

This results in a cleaner and safer environment for workers compared to mechanical cutting machines. Fumes from laser cutting can be effectively managed with exhaust systems.

Laser Cutting Fabric Applications

Laser technology is widely used across the fashion sector:

Garment Manufacturing

Lasers accurately cut pattern pieces for mass production of apparel. Complex patterns with sharp points and notches are easily cut.

Denim Jeans

Lasers cut and embellish denim with effects like fraying, perforations and distressing. This provides the worn-in appearance on jeans.

Accessories

Belts, purses, wallets and other accessories utilize laser cutting for patterning small and complex shapes from leather, faux leather and synthetics.

Footwear

Shoe uppers, linings and textile components are laser cut for greater precision. Laser cutting accommodates the small production batches typical for footwear.

Upholstery

Lasers cut fabric for furniture, automotive and marine upholstery including intricate shapes from heavy canvas and synthetic materials.

Technical Textiles

Specialty applications like airbags, sails and hot air balloons use laser cutting for high strength fabrics including Kevlar, fiberglass, carbon fiber and coated fabrics.

Home Decor

Laser cutting creates eye-catching designs on curtains, table linens, blankets and other home decor items.

Laser Cutting Fabric Equipment

There are several components that make up a complete laser cutting system:

Laser Source

As outlined earlier, CO2 lasers or fiber lasers supply the high intensity laser beam that is focused on the material being cut.

CO2 lasers are suited for cutting most fabric types, while fiber lasers provide extra precision on synthetics and delicate materials. The power of the laser determines the maximum cutting speed and thickness.

Beam Delivery

Beam delivery refers to the path the laser takes from the source to the cutting area. This may include mirrors or fiber optic cables to route the beam.

Lenses and mirrors in the cutting head focus the laser down to a tight spot size on the fabric. The focused spot intensity is what actually cuts the material.

Cutting Table

An adjustable height laser cutting table provides a work surface to handle the fabric. Downdraft holes in the table remove fumes and small particles from cutting.

Modern cutting tables include zones that can separately handle offloading and loading of material to maximize cutting time.

Exhaust System

A filtration unit with fume extractor is required to remove smoke, vapors and particles from the laser cutting process. Effective exhaust systems provide clean air and visibility for laser cutting.

Computer Control

Software allows operators to develop digital designs and cutting patterns. Computer numerical control (CNC) programs position the laser head and activate the laser beam to trace out these patterns on the fabrics.

Safety Enclosure

A Class 1 safety enclosure contains the laser cutting operation for the protection of workers. This includes interlocked access doors and window screens that block the laser light.

How To Successfully Laser Cut Fabric

Follow these tips to achieve the best results when laser cutting fabrics:

Choose the Right Laser

Select CO2 or fiber lasers based on the material types and cutting requirements:

- CO2 lasers are suitable for cutting all types of fabrics

- For synthetics and delicate fabrics, a fiber laser provides more precision

Optimize Laser Settings

Adjust laser power, speed, focus and assist gas pressure based on the fabric’s density, thickness and composition to achieve clean cuts.

Use lower power on delicate fabrics to prevent scorching around the cut edges. Higher power allows faster cutting of heavy fabrics.

Prepare Your Files Properly

Design files must be cleaned up and optimized for laser use. Convert stroked lines to outlined shapes and remove any unnecessary objects from the file.

Raster images may require adjustments to contrasts to translate properly into cut lines. Vector cutting lines should be set to a 0.001 inch thickness.

Use Correct Backing Material

Place fabric on materials like MDF board, acrylic or cardboard to support the fabric during laser cutting. This prevents melting or scorching from laser reflection off the cutting table.

Focus on Fabric Handling

Properly spreading, aligning, smoothing and securing fabric avoids problems like shifting and jams in the laser. Tightly rolled fabrics may require relaxing beforehand.

Assist Gas Choice

Oxygen assist gas gives the cleanest cuts on natural fabrics like cotton, wool and silk. Nitrogen works best for synthetics like polyester, nylon and spandex to prevent discoloration.

Clean Optics and Nozzle

Dirty or blocked lenses, mirrors and focusing nozzles can lead to uneven cuts. Regularly inspect and clean laser optics.

Exhaust System Maintenance

Change exhaust filters regularly and inspect ducts for obstructions to maintain proper airflow and smoke removal during laser cutting.

Safety First

Strictly follow all safety procedures including the use of personal protective equipment (PPE) like goggles and masks to avoid laser hazards.

Laser Cutting Fabric Troubleshooting

Here are solutions to some common laser cutting fabric problems:

Rough or Uneven Cuts

- Increase laser power/decrease speed for a more thorough cut

- Refocus the laser cutting nozzle at correct standoff height

- Clean laser optics like mirrors and lenses

- Replace assist gas nozzle if blocked

Discoloration, Scorching or Melting

- Reduce laser power settings

- Use appropriate assist gas for the fabric type

- Add backing material under delicate fabrics

Fabric Shifting During Cutting

- Use anchoring pins or vacuum hold-down to secure fabric layers

- Tightly spread fabric flat without wrinkles or billows

- Clean cutting table surface for proper vacuum hold-down

Fabric Jam in Machine

- Inspect fabric edges for fraying or defects before cutting

- Adjust fabric roll tension to prevent loose fabrics

- Slow down machine cutting speed

- Ensure proper nozzle standoff height

Laser Cannot Penetrate Fabric

- Increase laser power to cut through thicker fabrics

- Decrease cutting speed for more laser energy exposure

- Upgrade to higher powered laser source if fabric is too dense

Burning Odor

- Install or upgrade exhaust filtration unit

- Change exhaust filters if blocked with residue

- Increase assist gas pressure to remove cutting smoke

Laser Cutting Fabric Safety

Laser cutting systems generate visible and invisible laser radiation that can cause serious injury. Operators should undergo extensive training and always follow safety precautions:

- Use a Class 1 laser enclosure with interlocked doors and screens

- Wear appropriate PPE like laser safety goggles and masks

- Never override or tamper with machine safety features

- Avoid direct eye contact with laser beam

- Post clearly visible warning signs on the machine

- Establish nominal hazard zones with access restrictions

- Keep system maintained according to manufacturer guidelines

- Develop lockout procedures for maintenance

- Provide adequate facility ventilation and exhaust

Conclusion

Laser cutting enables lean, automated and precise fabric cutting that outweighs limitations of mechanical cutting methods. With the right laser system, technique and safety measures, lasers produce quality cuts across a wide range of fabrics.

Laser cutting transforms the economics and capabilities of fabric manufacturing. The technology offers apparel and textile companies the accuracy, speed, flexibility and productivity needed to excel in the modern marketplace.

Frequently Asked Questions

What types of fabric can be laser cut?

Laser cutting is suitable for almost all types of woven and non-woven natural and synthetic fabrics. Everything from delicate silks to heavy denim and canvas can be successfully laser cut.

What thickness of fabric can a laser cut?

Laser cutting capacity depends on the power of the laser but most systems can cut fabric up to around 1/4 inch thick. Thicker fabrics may require multiple passes to cut through the entire thickness.

Is laser cutting fabric safe?

With proper use of machine safeguards, personal protective equipment, and following operational safety procedures, laser cutting fabric does not pose unreasonable risks to worker health and safety. Proper facility ventilation and exhaust systems help maintain air quality.

How precise is laser cutting of fabric?

Laser cutting of fabric can achieve a positional accuracy within 0.001 inches and repeatability of 0.0005 inches. This results in smooth, clean edges with tight tolerances for precision patterning.

What software is required for laser cutting fabric?

A CAD program is used to design cutting patterns which is then converted to CNC machine code to control the movements of the laser. Popular programs include Adobe Illustrator, CorelDRAW and AutoCAD for design, and RDWorks for generating the CNC toolpaths.